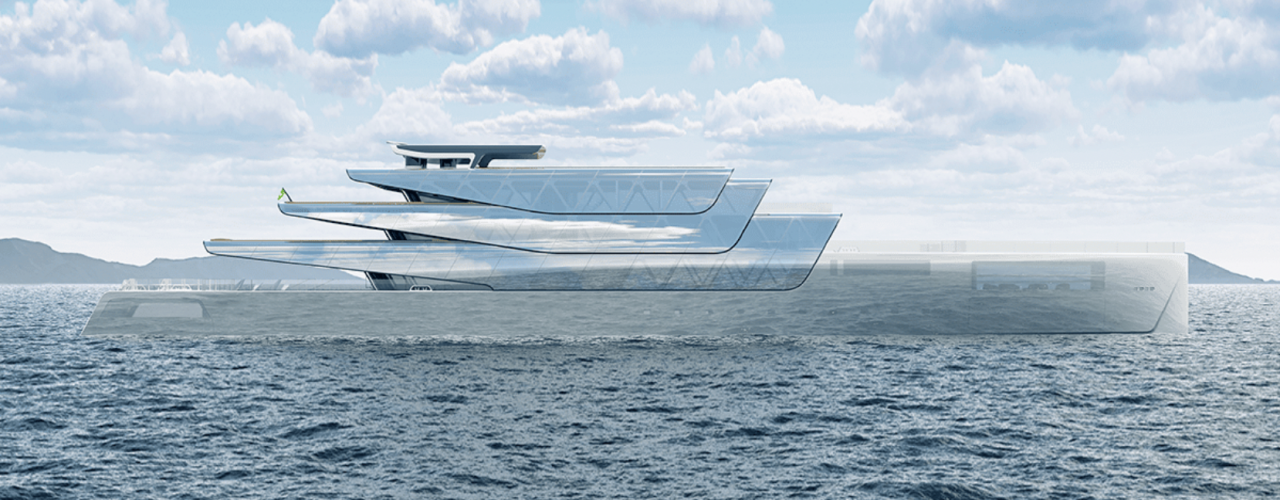

Superyachts are the epitome of luxury and extravagance. These floating palaces are designed to provide an unforgettable experience to their owners and guests. With the advancement of technology, 3D design printing has made its way into the world of superyacht design, revolutionising the way these vessels are built. In this blog, we will explore the benefits of 3D superyacht design printing, the process involved, and how it it is changing the Superyacht industry.

What is 3D Superyacht Design Printing?

3D superyacht design printing is a technology that allows designers and builders to create physical models of Superyachts using advanced printing technology. 3D printing is a process of creating three-dimensional objects by adding layers of material on top of each other until the desired shape is formed. The technology has been used in a variety of industries, including aerospace, automotive, and medical, and more recently, the Superyacht industry.

Benefits of 3D Superyacht Design Printing:

- Faster design process: One of the major advantages of 3D superyacht design printing is that it speeds up the design process. Traditional methods of designing yachts involved creating physical models or mock-ups, which are often time-consuming and expensive. With 3D printing, designers can create and test various designs quickly and easily, making it easier to bring new concepts to life.

- Cost-effective: 3D superyacht design printing is more cost-effective than traditional methods. It reduces the cost of materials and labor, as the process involves creating a digital model and printing it using a 3D printer. This means that the cost of creating multiple design options is significantly lower, making it easier for yacht builders to experiment with different designs.

- Precision and accuracy: 3D printing ensures precision and accuracy in the design process. The technology allows designers to create complex geometries and intricate details that may not be possible with traditional methods. This ensures that the final product is of the highest quality and meets the client’s exact requirements.

The Process Of 3D Design Printing

- Conceptual Design: The first step is the conceptual design of the yacht. The designer creates a digital 3D model of the yacht, which is used as the blueprint for the entire process.

- 3D Printing: The next step is 3D printing. The designer uses a 3D printer to create a physical model of the yacht. The printer builds the model layer by layer using the blueprint created in the previous step.

- Testing: Once the physical model is printed, it is tested to ensure that it meets the design specifications. This step is crucial as it allows designers to identify any design flaws or issues that need to be addressed before moving on to the final production phase.

- Final Production: After testing and making any necessary adjustments, the final production phase begins. The yacht is built according to the 3D model created in the first step, ensuring that it meets the client’s exact requirements.

READ MORE – An Interview With Njord by Bergman Design House: M/Y Galaxy Refit

But How is 3D Superyacht Design Printing Changing the Industry?

- Faster Design Process: The use of 3D printing has significantly reduced the time it takes to design a superyacht, making it easier for designers to experiment with new ideas and bring them to market faster.

- Reduced Costs: 3D printing has also reduced the cost of designing and building superyachts. This means that yacht builders can offer more competitive prices to their clients, making it easier for them to access the luxury market.

- Improved Quality: 3D printing ensures that the final product is of the highest quality. This is because the technology allows for greater precision and accuracy in the design process, resulting in a more refined final product.

Superyacht Designers who have embraced 3D Design Printing:

Several renowned superyacht designers have embraced 3D superyacht design printing as a way to improve the design process and create more innovative vessels. Here are a few examples:

-

Philippe Briand: Philippe Briand is a French superyacht designer who has used 3D printing extensively in his work. He has worked on several high-profile projects. Briand uses 3D printing to create a physical models of the yachts, which allowed him to test the design and make any necessary adjustments before beginning the production phase.

-

Benetti: The Italian superyacht builders have been using 3D printing for several years. The company uses the technology to create physical models of its yachts, which allows designers to test the design and make any necessary changes before production begins. Benetti also uses 3D printing to create custom components for its yachts, which improves the accuracy and quality of the final product.

-

Zaha Hadid Architects: Zaha Hadid Architects is a London-based architecture firm that has used 3D printing in several of its superyacht designs. The firm used the technology to create a physical model of the 128-meter superyacht Jazz, which features a striking design inspired by fluid dynamics. The 3D model allowed the designers to test the design and make any necessary changes before construction began.

- Feadship: The Dutch superyacht builders have also embraced 3D printing in its design process. Similar to Benneti, the company uses the technology to create physical models of their yachts, which allows designers to test the design and make any necessary changes before construction begins. Feadship has also used 3D printing to create custom components for their yachts, such as intricate metalwork and decorative features.

These are just a few examples of the many superyacht designers and builders who have embraced 3D printing as a way to improve the design process and create more innovative vessels.

In conclusion, 3D superyacht design printing is set to continue transforming the yachting industry due to all of the above aspects. The technology has opened up new possibilities for yacht designers and builders, allowing them to create more innovative and extravagant vessels. As the technology continues to evolve, we can expect to see even more designers and builders incorporating it into their work.

For the latest Superyacht Content news, click here.

.gif)

.gif)